WP1 results: CFD Modelling

Cavitation causes flow instabilities that hampers the functioning of flow devices, primarily by increasing the noise level, vibration, and, in extreme cases, the devices’ erosion.

Experimental tests have been carried out on two Magallanes tidal turbines. By tuning the turbines’ external pitch angle, we can achieve the “load-balancing” in terms of power output from both the turbines.

WP1 results: Cavitation testing

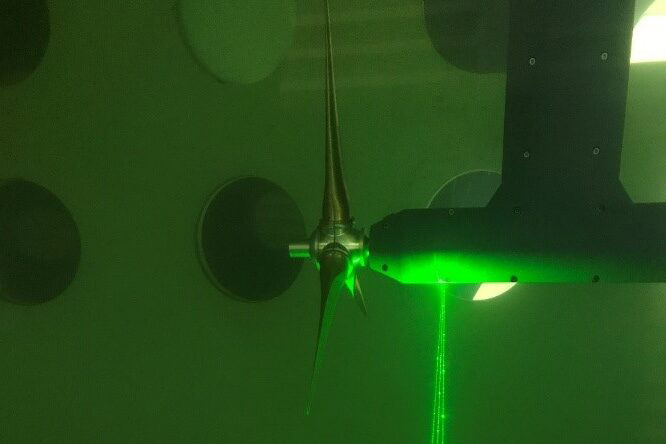

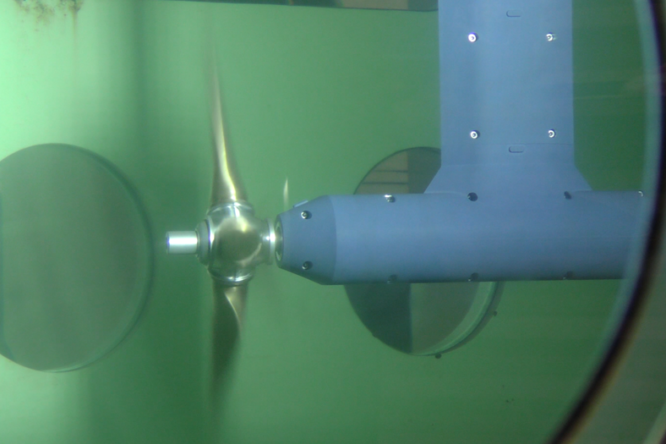

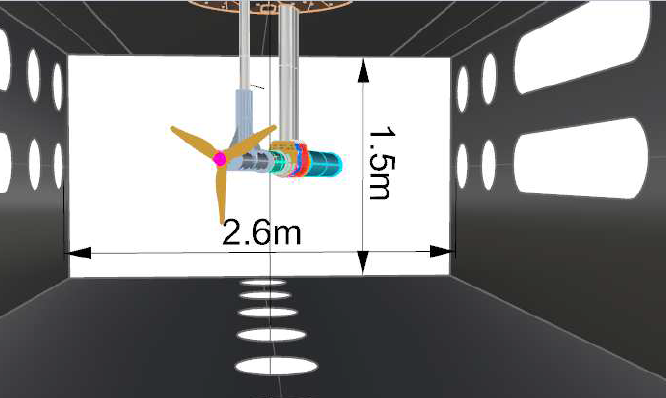

Optimizing the turbine geometry requires rigorous investigation of hydrodynamic behaviour of blades and their interaction with the supporting structure and nacelle. SSPA has performed experimental tests in order to provide a baseline for further improvement of the blade design by evaluating the performance of the model turbine and measuring the flow field using Laser Doppler Velocimetry (LDV) method.

WP1 results: Active control of hydrofoil cavitation testing

Tidal turbines play a crucial role in providing sustainable and pollution-free energy. In tidal turbines, cavitation is an important phenomena in determining the life span of the turbines.

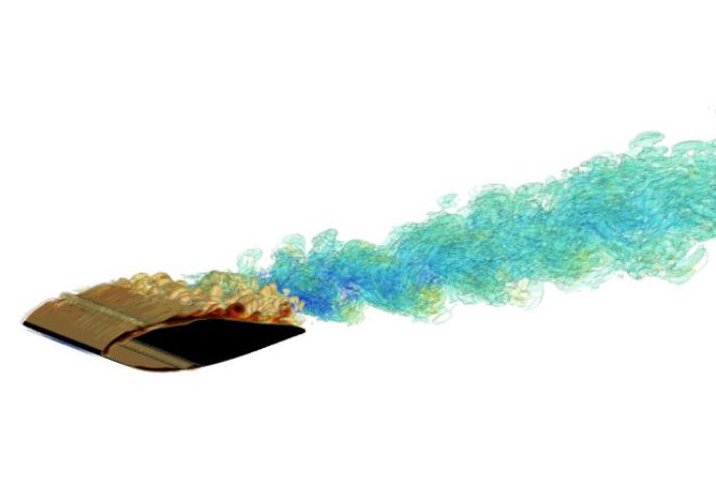

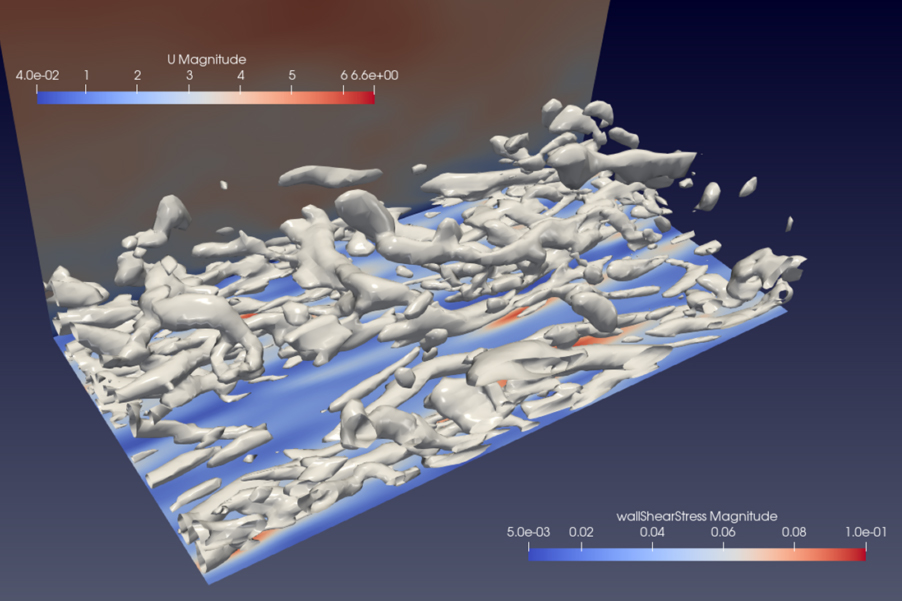

NEMMO project partner Technion (Israel Institute of Technology) has developed and performed a high-order Large Eddy Simulations (LES) code, called MIRACLES, to study cavitation sheet dynamics associated with the modified scaled-down Francis turbine (hydrofoil) at angle of attack (AOA).

This research paper focuses on elucidating and analysing the re-entrant jet dynamics. Active cavitation control via steady wall jet injection was studied, but it had limited effect for the flow conditions (injection velocities and AOA) considered.

The results of this study are now available on the ScienceDirect: Interaction between surface blowing and re-entrant jet in active control of hydrofoil cavitation.

Further study on LES of wind (and tidal) turbines using a Filtered Actuator Line Model (ALM) has been carried out based on the outcome of the previous study. This study encourages accurate and affordable simulations of multirotor devices in the future.

The result of this study is now available on the ScienceDirect: Large-Eddy Simulation of a wind turbine using a Filtered Actuator Line Model.

Moreover, a detailed flow analysis of the fluid dynamics associated to a pair of counter-rotating turbines in a tidal device was performed. Large Eddy Simulation (LES) was conducted using the actuator line method, and the resulting flow was scrutinized by employing proper orthogonal decomposition (POD). The flow field was then reconstructed using the reduced order method.

The result of this study is now available online: Efficient flow reconstruction between dual tidal turbines: Large eddy simulation and reduced order modeling approach

WP1 results: Advances in LES simulation for accurate definition of instant hydrodynamic loads

This article summaries the work carried out under Work Package 1 “MIRACLES: LES Simulation Code for Turbine Blade Operation”, which aims to develop and apply a computational fluid dynamics (CFD) model for simulating tidal turbine blade cavitation in order to explore various passive and active cavitation control strategies and then consider implementing them on a full model of a multi-bladed tidal turbine.

WP2 results: Novel tests-rigs to define the best Active Flow Control strategies for tidal turbine blades

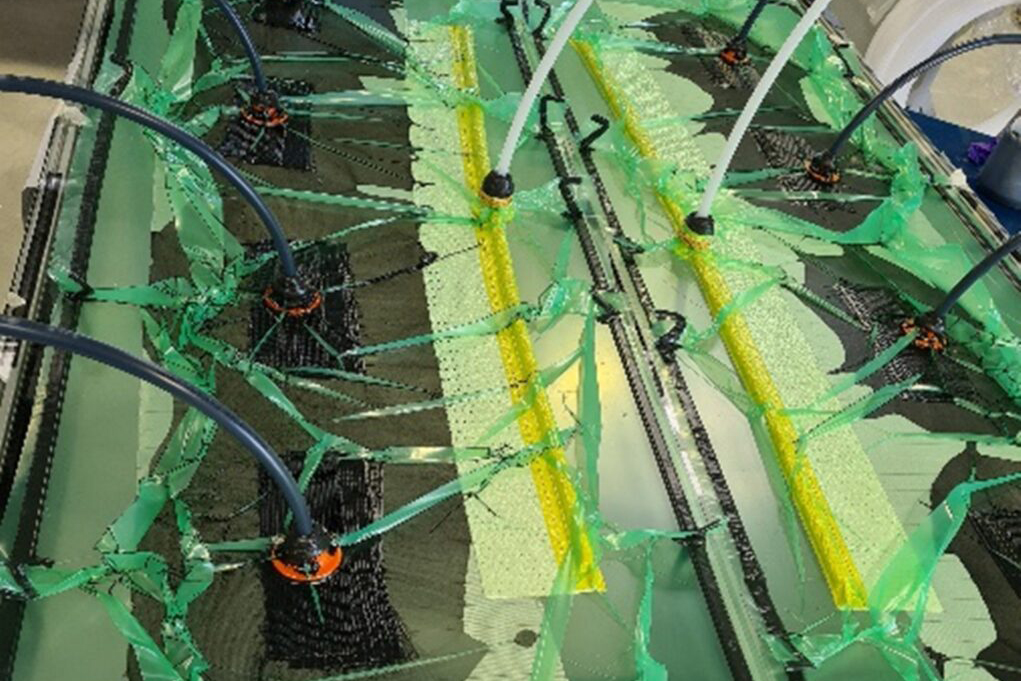

The NEMMO project team have designed and built novel test-rigs to define the best AFC (Active Flow Control) strategies for improving the performance of tidal turbine blades.

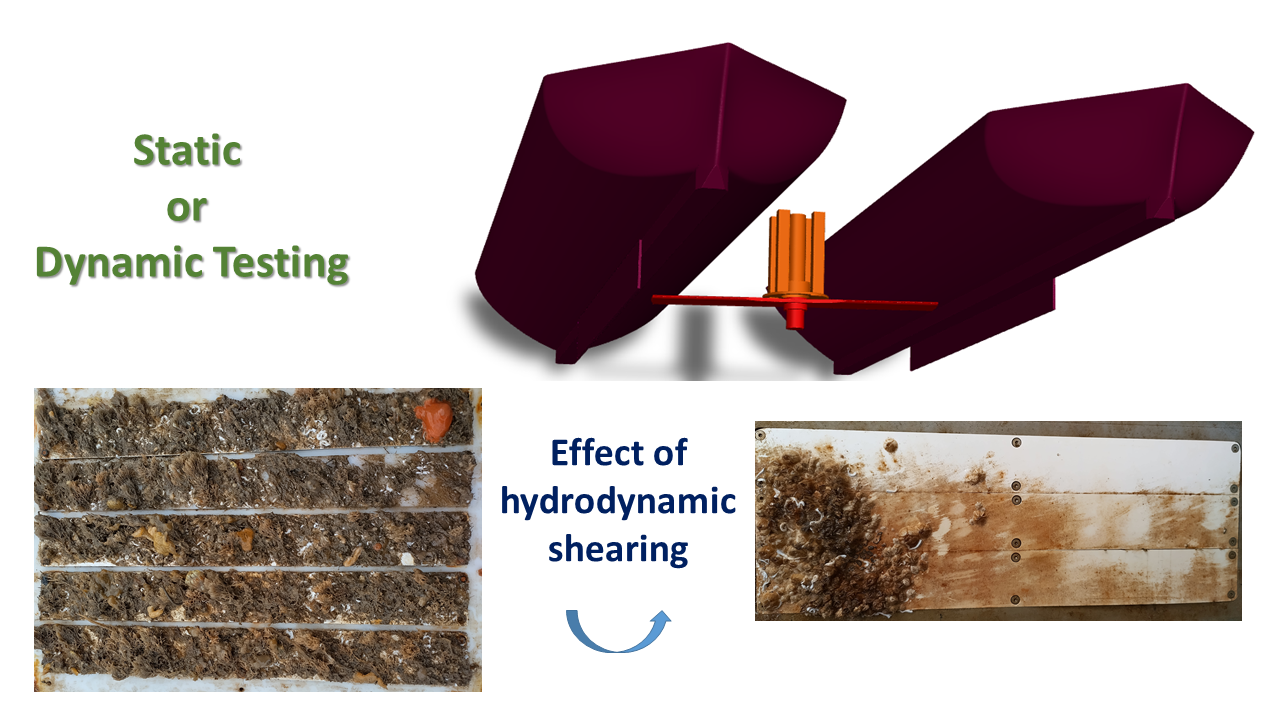

Tailor-made testing procedures were developed to carry out a sizeable experimental test programme in SSPA’s cavitation tunnel. These testing procedures for integrated harsh marine stresses enable the replication and modelling of composites blades’ lifespan, cavitation wear rates, bio-fouling growth, ageing in a harsh marine environment and hydrodynamic performance.

WP2 results: Novel testing procedures to enhance tidal composite blade performance

Tidal turbines are a promising opportunity to exploit ocean current flows clean energy production. To enhance tidal turbine blade performance using composite materials for tidal energy generation, the NEMMO project team designed a novel testing and characterization protocol to evaluate blade material degradation caused by the exposition to the sea water environment.

WP2 results: Active Flow Control (AFC) appendages

This article summaries the work carried out in Work Package 2 on Active Flow Control (AFC) appendages, covering the assessment of AFC in tidal composite blades and testing of AFC appendages on tidal turbine and validation of High Fidelity LES Models. Best performing AFC appendages for tidal blades composite has been identified.

WP3 interim results: Materials & coatings

Developing novel materials and coatings for tidal turbine blades is one of the main objectives of the NEMMO project.

Three parallel approaches have been used to enhance blade material performances in order to increase their ageing, fouling, impact, and cavitation resistance:

- Improving the fatigue and impact resistance of the new nano-enhanced composite materials.

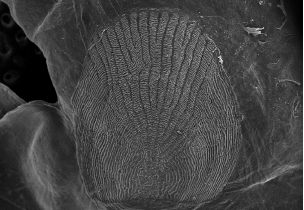

- Controlling biofouling by means of blade surface micro-texturing.

- Developing novel non-leaching anti-fouling coatings with permanent cavitation resistance through the design and synthesis of polymers bearing different functionalities within its chemical backbone and the incorporation of functionalized nanoparticles into such polymer formulations.

WP3 interim results: Surface textures

Part of the NEMMO project has been dedicated to designing an effective texture tailored to the NEMMO turbine. Bio-inspired surface modification has shown potential as an antifouling strategy. The surface textures can act on the ability of fouling micro-organisms to find secure attachment to the substrate but also alters fluid induced stresses over the organisms. The two effects combine to reduce initial settlement and improve the self-cleaning properties of the surface by altering cell adhesion in turbulent flows.

WP3 results: Novel composite materials to enhance the resistance of tidal turbine blades

The NEMMO project team has recently published novel composite material solutions to enhance the resistance of tidal turbine blades. Key test results are presented along with an outline description of the methodologies adopted. This study focuses on three parallel approaches adopted to enhance blade material performance.

This research helps the NEMMO project reach its ambitious targets to drive down maintenance costs due to cavitation wear, bio-fouling and ageing, and to enhance hydrodynamic performance.

WP4 results: Advanced composite blade designs for enhanced lifespan and performance

The NEMMO project team has worked on the novel material solutions and blade design to enhance the resistance and durability of tidal turbine blades. Key test results are presented along with an outline description of the methodologies adopted. A full-scale blade prototype would be built and tested to compare the new blade behaviour against test results with the current blade.

This research helps the NEMMO project reach its ambitious targets to drive down maintenance costs due to cavitation wear, bio-fouling and ageing, and to enhance hydrodynamic performance.

WP5 results: Ageing, Fouling and Wear Behavioural Modelling

The NEMMO project has recently completed a study on developing a biofouling behavioural model, which captures the dynamic growth of biofouling organisms as observed on different material solutions. This 8.5-month marine test campaign was conducted in Dublin by Dublin City University. A variety of anti-fouling material solutions were tested under realistic conditions for their fouling and ageing performance.

WP5 results: Numerical methodology for the estimation of tidal blades life under damage tolerance considerations

The NEMMO project has defined a methodology to simulate a whole tidal blade, identify and simulate critical sections and obtain fast results on the detailed models when applying different load spectra on the tidal blade was defined and applied to a tidal blade design.

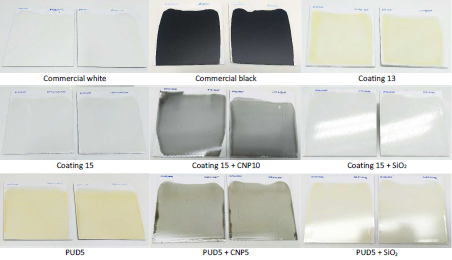

WP5 results: Coatings and textures for non-toxic and non-leaching wear, aging and fouling protection

Fight against fouling is another relevant objective in the project, and two different approaches were explored: surface micro-texturing and antifouling coatings.

The NEMMO project partner DCU carried out experiments to identify suitable coatings and textures for non-toxic and non-leaching wear, aging and fouling protection.

WP6 results: Life Cycle Assessment

The NEMMO project team recently conducted a life cycle assessment to identify the environmental impacts that may arise during the NEMMO project’s life cycle.

WP6 results: New socio-economic assessment on potential socio-economic benefits to local Scottish and Welsh communities

The NEMMO project team recently conducted a socio-economic assessment to identify the possible socio-economic impacts that may arise during the NEMMO project’s life cycle.

Key survey results are presented along with an analysis of two scenarios focusing on the potential development sites, i.e., Scotland (Fall of Warness tidal site) and Wales (Morlais tidal site), where local economies could benefit from the tidal project.