Last updated 8 April 2021

Work Package 3 includes the development of novel materials and surface treatments for NEMMO’s tidal turbine blades with the aim to increase their ageing, fouling, impact, and cavitation resistance.

The work targets three parallel approaches to enhance blade material performances:

Improving the fatigue and impact resistance of the new nano-enhanced composite materials.

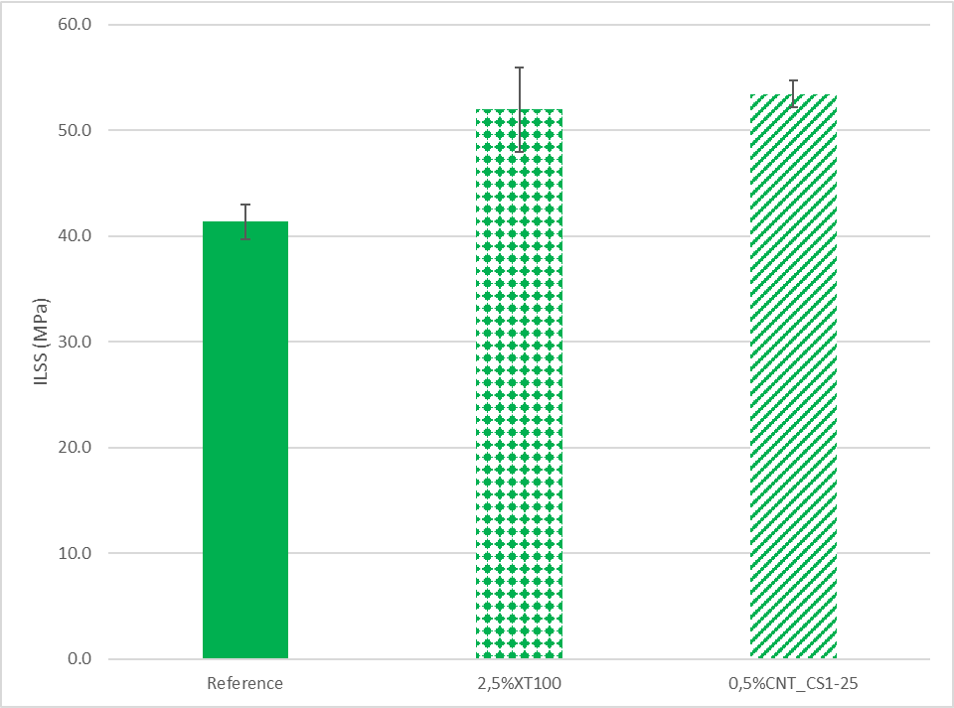

Several formulations including carbon nanotubes (CNT) and impact modifiers to the reference resin have been prepared and tested. Composite plates of glass fiber reinforced vinylester resin have been successfully manufactured by infusion process for each formulation. Mechanical characterisation of each composite including in plane characterisation (longitudinal, transverse, +/-45° tensile traction), ILSS and Charpy impact testing have been done. There is a strong dependency of the formulated resin for ILSS and +/-45° tensile tests (in-plane shear). Other mechanical properties seem to be similar whatever the formulation. Also, humid ageing assays have also been carried out to assess moisture effect onto formulated materials.

Controlling biofouling by means of blade surface micro-texturing.

Samples of surface micro textures blades were submerged over a 5-month period at a costal site in Ireland. Biofilm growth has been characterised through stage assessment of the protein and carbohydrate concentrations and of the population dynamics of key fouling organisms. Two organisms suitable for a lab-based evaluation of the antifouling performance of candidate biomimetic textures have been selected and grown in the lab. Four candidate biomimetic micro-textures have been defined and two alternative production methods have been tested. Samples have been produced using 3D printing and laser etching has been tested to confirm feasibility. Also, high fidelity turbulent flow simulations have been performed to evaluate the effect of candidate micro-textures on local hydrodynamic stresses. The final phase of the study will assess the impact of textures on how micro-organisms settle on the surface and how this in turn affects the adhesion strength. Centrifugal and hydrodynamic tests are outstanding and are required to confirm which candidate micro-textures provides the best antifouling performance.

Developing novel non-leaching anti-fouling coatings with permanent cavitation resistance through the design and synthesis of polymers bearing different functionalities within its chemical backbone and the incorporation of functionalized nanoparticles into such polymer formulations.

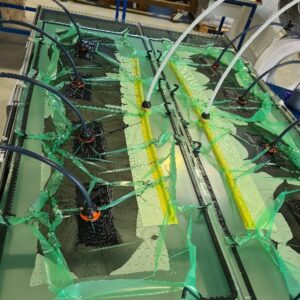

Several candidate formulations were formulated and applied on glass and composite substrates. As result of their good mechanical properties, glass transition temperature and different hydrophobicity behaviour that can either prevent the biofouling or improve the release of settled biofouling by the water flow, two types of formulations were selected. The mechanical properties of the coatings and their biocide activity were measured. The natural ageing with a high amount of fouling is being done in the Port of Pasaia facility. This exposition site is especially suitable to test antifouling solutions due to its estuarine port conditions with a mix of sea water.