Nanotechnology being deployed to combat blade fatigue and impacts

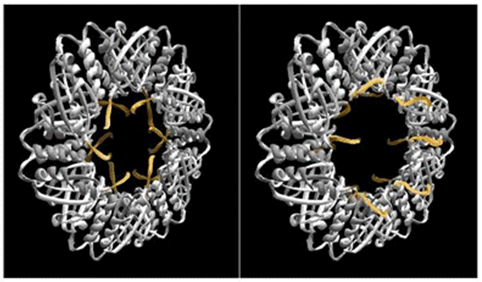

The project team has been hard at work developing new, stronger composites for tidal turbine blades. These innovative materials are fortified with carbon nanoparticles, nano-complexes and copolymers – some of which borrow from the natural world, such as SP Nano’s SP1 protein originating from the Aspen tree.

The fibreglass used for the blade structure is infused with these complexes, which makes it stronger while maintaining its lightweight qualities.

By using these new composites, the team anticipates that the blades will be more resistant, less likely to fail and will last longer in tough sea conditions. The mechanical performance of the new composites will now be compared to ‘standard’ reference materials in a climatic chamber, where they will be subjected to different temperatures and humidity levels.

The project’s work on blade materials comes under Work Package 3: Nano-reinforced composites, antifouling coatings and antifouling biomimetic surfaces.

Biofouling is the process by which microorganisms, plants, algae, or small animals accumulate on a blade’s surface, which reduces the performance of the blade and the power output of the turbine as a whole.