Initial NEMMO model results show high levels of accuracy

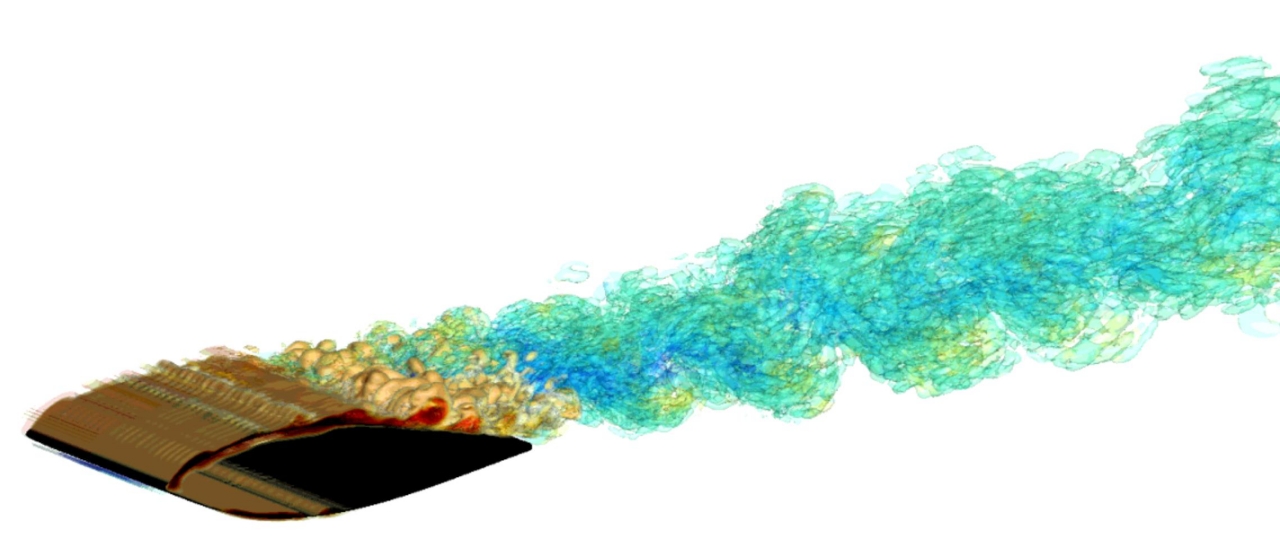

A new computer model, designed by the NEMMO project to simulate the effect of water flows over a tidal turbine blade, has shown high levels of accuracy when compared with real-life data. The model, created using CFD (Computational Fluid Dynamics) techniques, demonstrates the wear and tear on a hydrofoil’s surface caused by turbulence as water flows across it.

Project partner Technion has integrated new cavitation models into their cutting-edge computer code. Cavitation, whereby bubbles caused by pressure variations burst and damage the blade’s surface, is a major cause of wear on tidal turbine blades.

This simulation marks the completion of the first step towards completing Work Package 1. The next step is to adapt the modelling code to include control strategies that passively or actively reduce cavitation. Further simulations will then be performed to validate the model and gain insight into reducing wear on the next generation of tidal turbine blades.